ECD Grinding

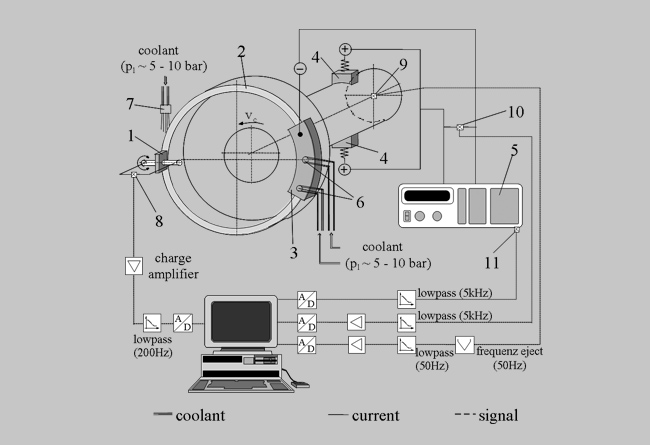

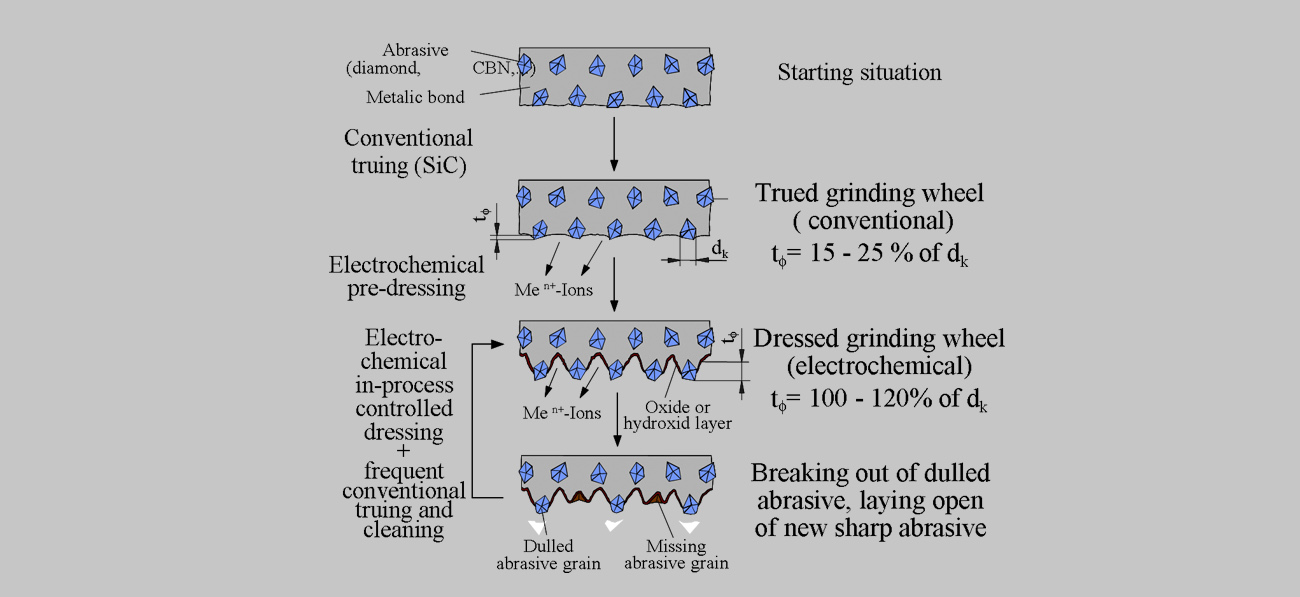

The application of a voltage between the two electrodes leads to the dissolution of the metallic bonding system, which is dissolved into its ions, or converted into hydroxides and oxides. The bonding of the grinding wheel is dissolved and set back behind the abrasives peaks. Dulled abrasives are released from the bonding and an optimal protrusion of the abrasives is the result. The sharpening speed is proportional to the rate of dissolution of the metal bond, which could be controlled according to Faraday's law with the power source. The G-value, the relationship between removed work piece volume and worn grinding wheel volume, can be adjusted by taking into account the volume of removed work piece material over the current.

The ECD grinding process works with bronze bonded diamond or CBN grinding wheels. In contrast to conventional conditional concepts the ECD can dress also very fine-grained grinding wheels (e.g. MD 4 - MD 10) with high concentration up to C (B) 200. In addition, the ECD method doesn’t picture the kinematics of the conditioning process on the grinding wheel topography. The reachable protrusion of grit on ECD dressed grinding wheels can be up to 100% of the grain diameter.

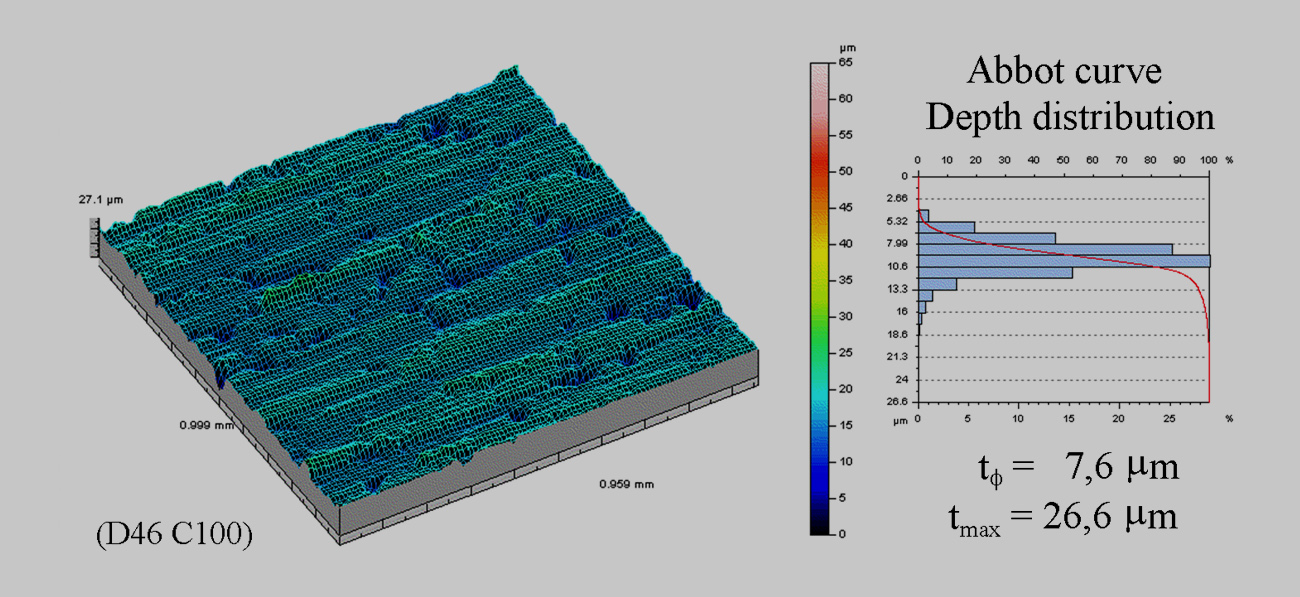

Conventional SiC dressed grinding wheel

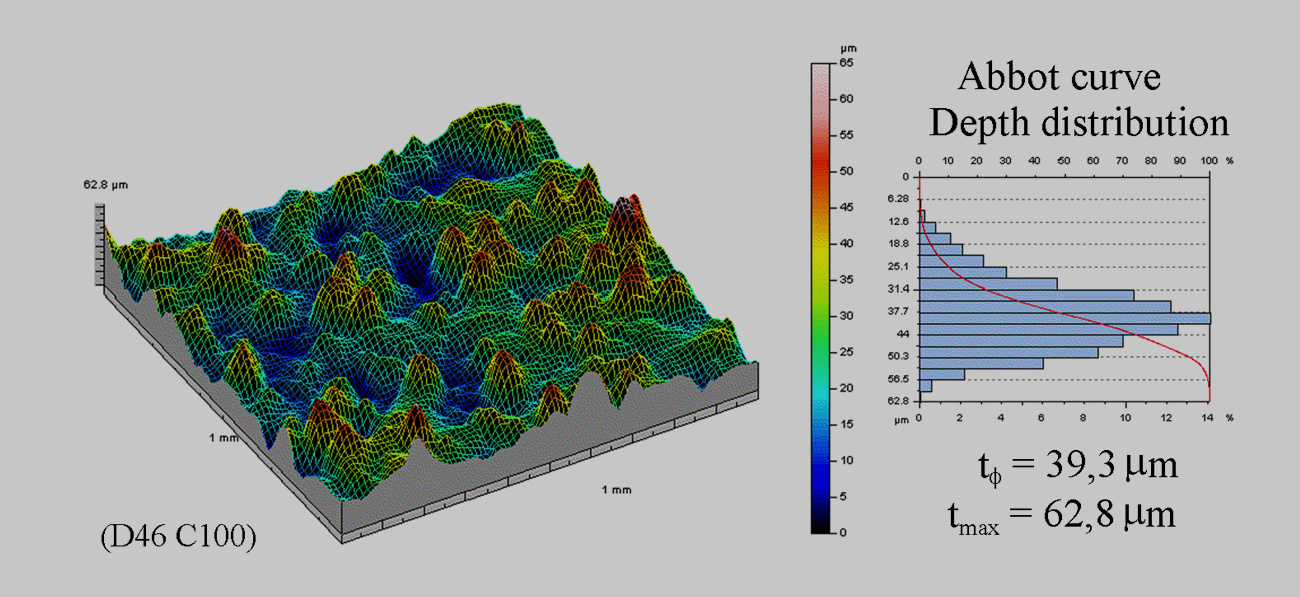

ECD dressed grinding wheel

As the comparison of the 3D grinding wheel topography measurements clearly shows the ECD grinding opened completely new possibilities in the finishing of modern cutting materials – especially in economic terms!

Technical modifications reserved.

For a number of products of ProGrit GmbH, patents have been granted or are pending.

Copyright © ProGrit 2017

- Kastellstrasse 6 · 8623 Wetzikon / Switzerland ·

- Tel: +41 (0)44 844 54 26 ·

- info@progrit.ch

.jpg)

.jpg)