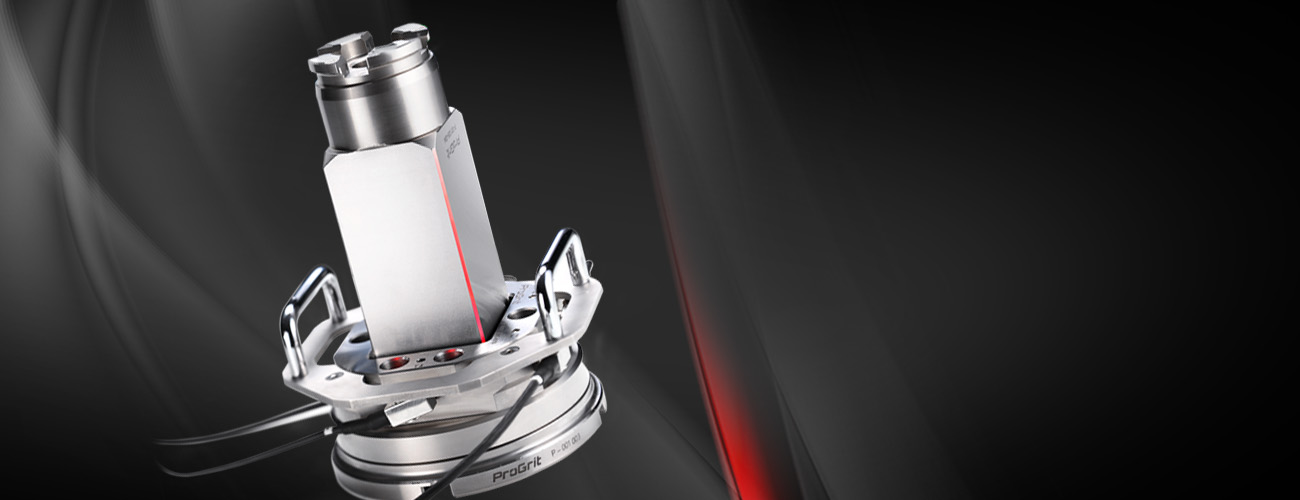

Powder Compaction Tooling

ProGrit provides system solutions for different requirements - from tool design, compaction tools over the tool shop up to the reference clamping systems for the presses.

Precision / Compaction Technology

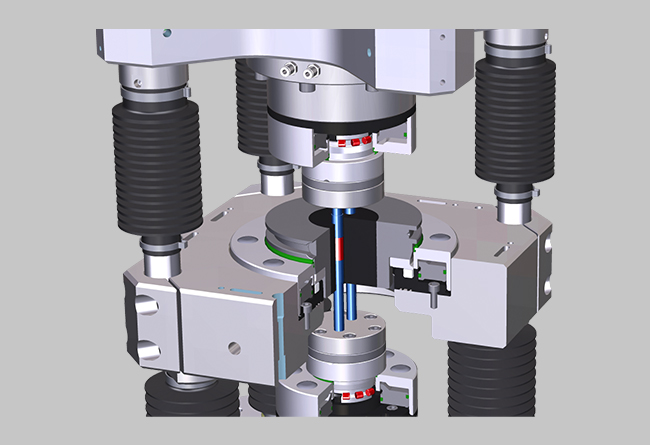

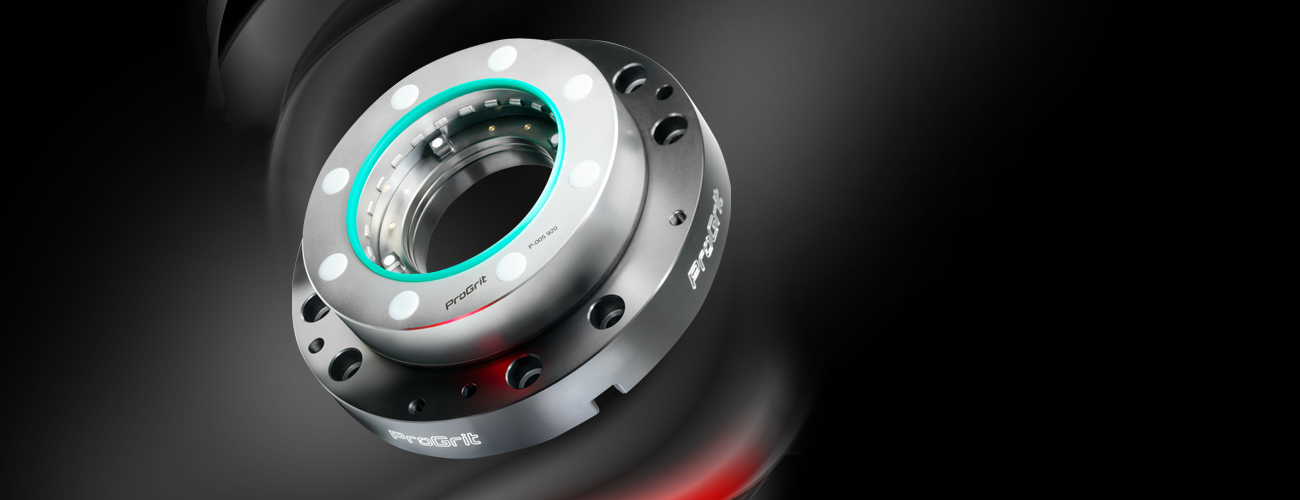

Burr free or burr less compacting requires highest precision in the tool shop, the press and the compaction pro-cess. The Powder Compaction System of ProGrit achieves this precision by high precision positioning of the tool clamping system and precise alignment of these positioning systems to each other in the press.

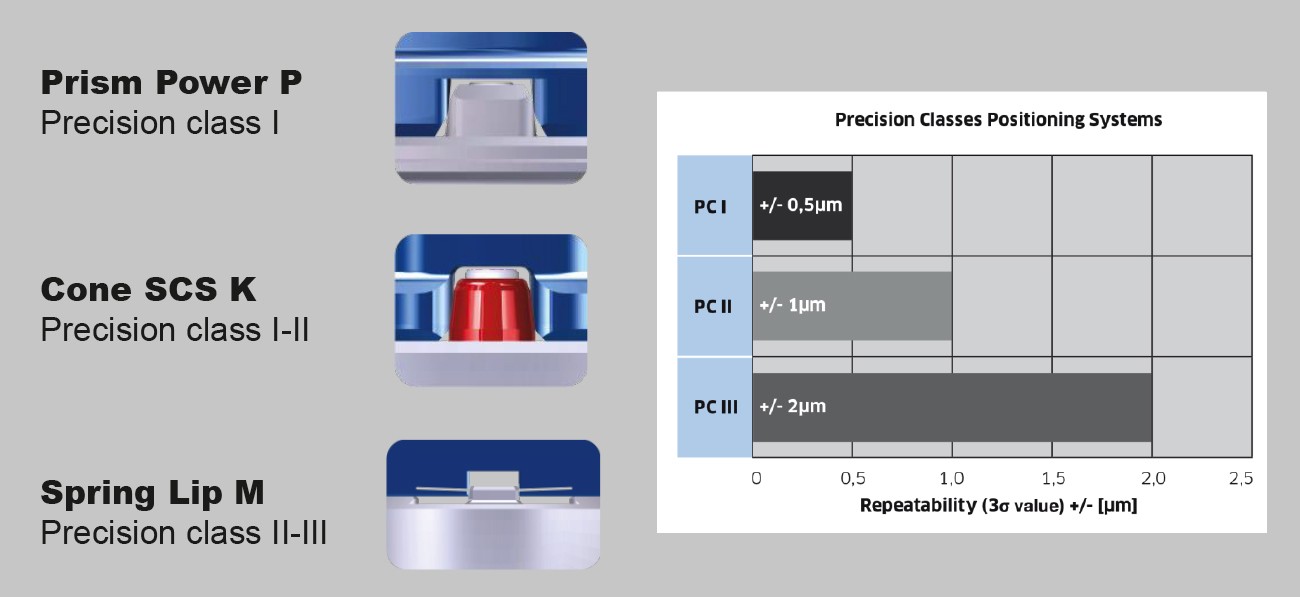

Positioning Systems – Precision Classes

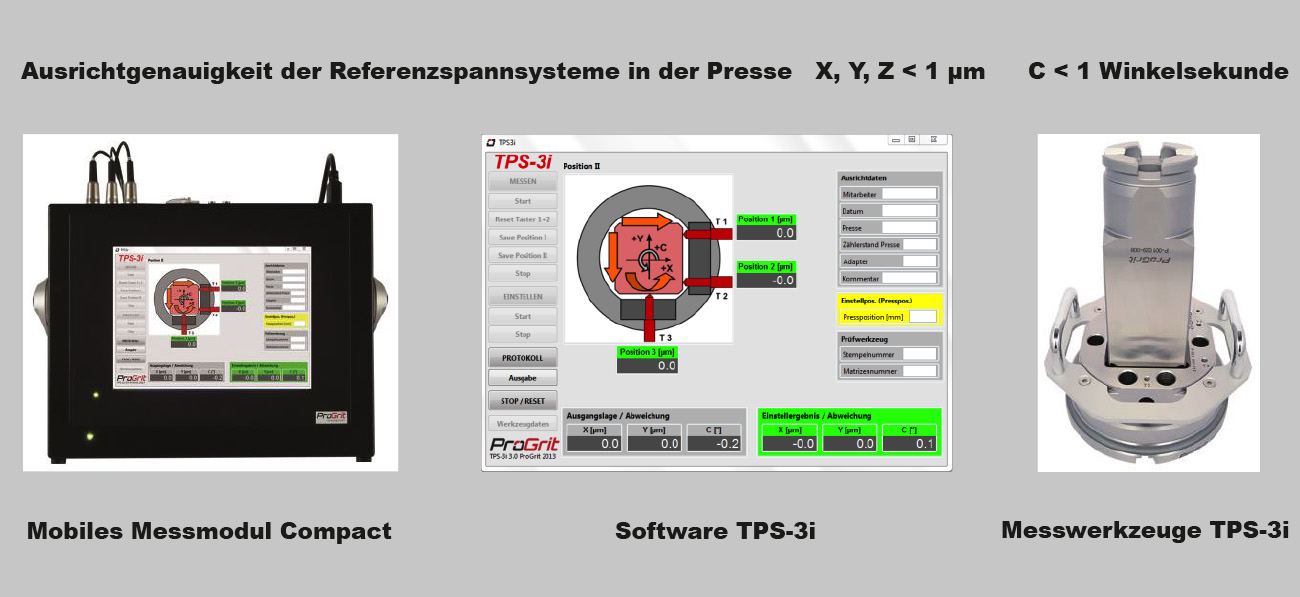

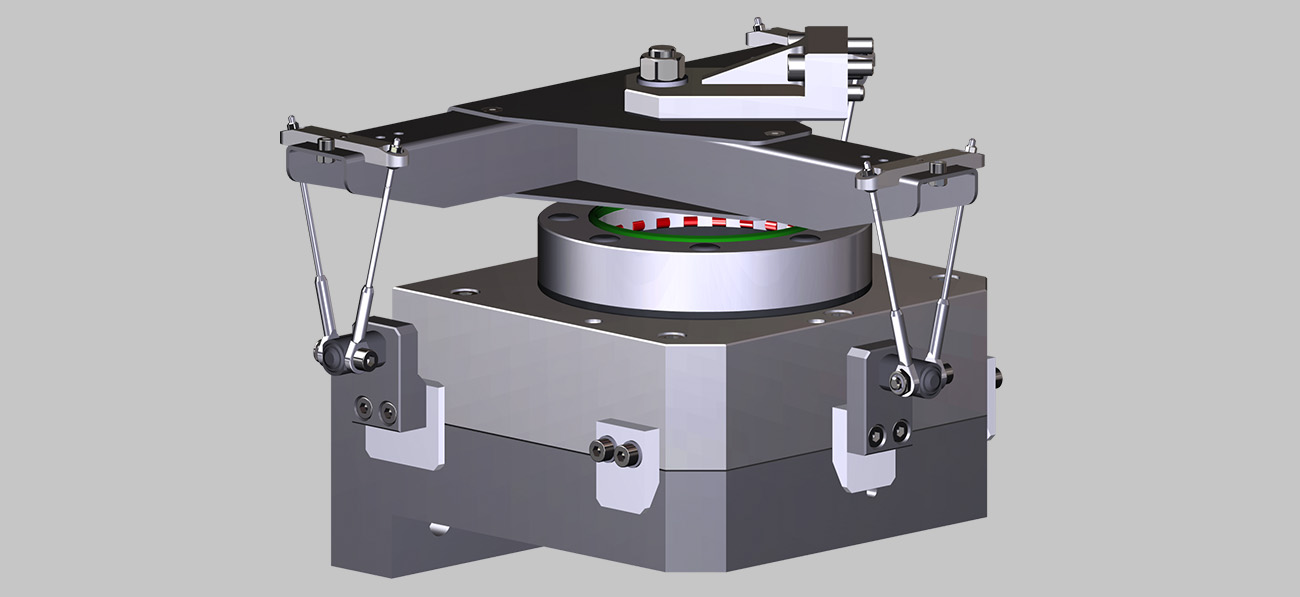

Alignment System TPS-3i

The Tooling Positioning System TPS-3i is able to align the reference clamping systems in the press in an accuracy of X, Y, Z better than 1 micron and in C better than 1 arc second to another. A perfect symmetrical distribution of the compaction clearance can be guaranteed through the TPS-3i technology.

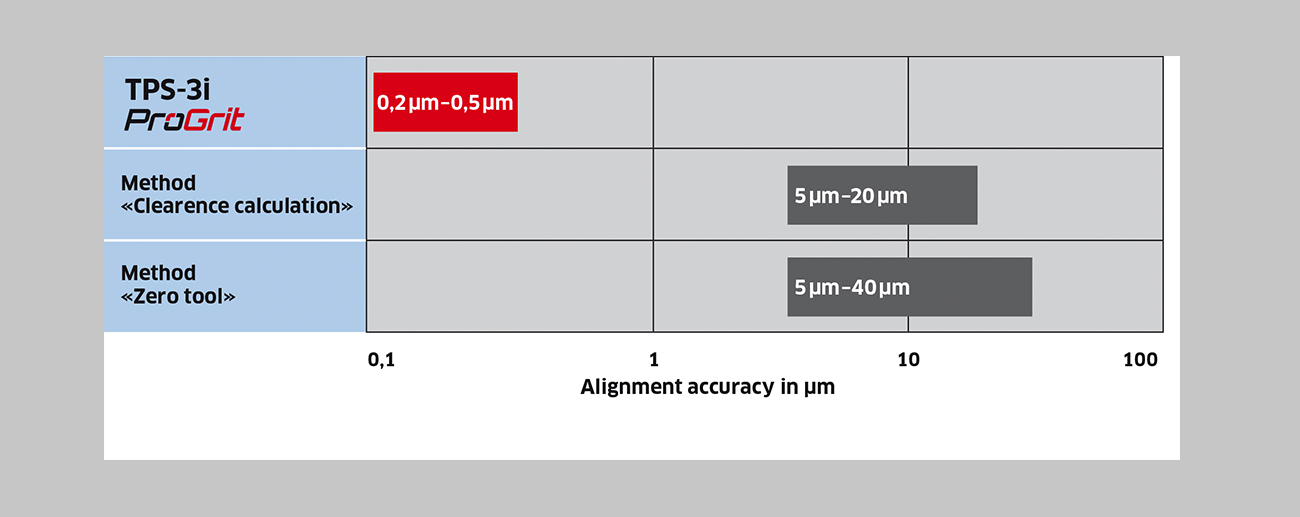

Comparison of alignment accuracy for different alignment technologies:

The ProGrit TPS-3i alignment technology delivers 10 to 40 times higher alignment accuracy than other on the market available alignment technologies.

Productivity – Set Up Times

Cost reduction by reducing set up times and concurrent elimination of tool damage in the compacting process results in pay back times of less than 0,5 years for the investment in a Powder Compacting Tooling System.

Total set up time = Change of tools + Alignment of tools

Consulting & Engineering over the whole Powder Compaction Technology Chain

ProGrit supplies customized developments, concepts und solutions for

- Reference clamping systems for single and multi-level applications

- Co axial compaction – splitted punch

- Multi axial compaction – cross hole, closed, open and splitted die

- Compaction with multi cavities

- Design and standardization of compaction tools and filler plates

- Development of manufacturing concept for the tool shop

- Measurement technology for measurement, correction and referencing of presses and die sets

- Measurement technology for alignment of reference clamping systems in the press

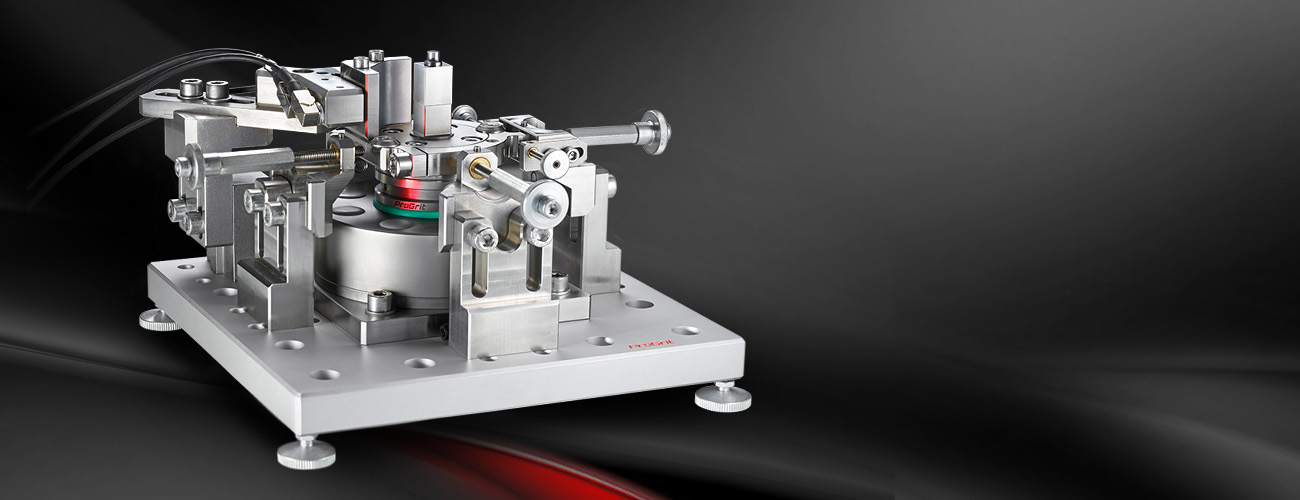

- Palletization technology for positioning of existing compaction tools and position correction of new produced compaction tools

- System integration in press and die set

- Production technology and adaption and set up of the tool shop

- Full automated powder and compaction tool change

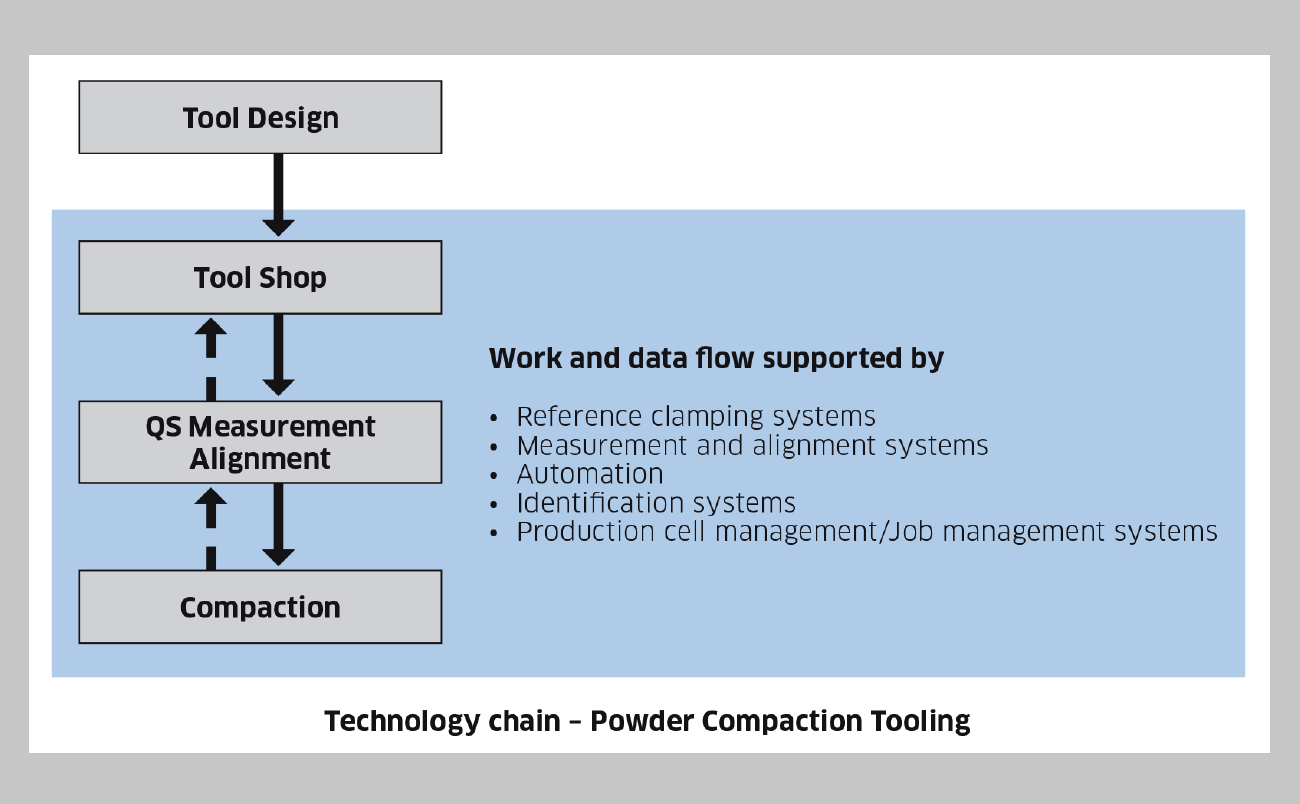

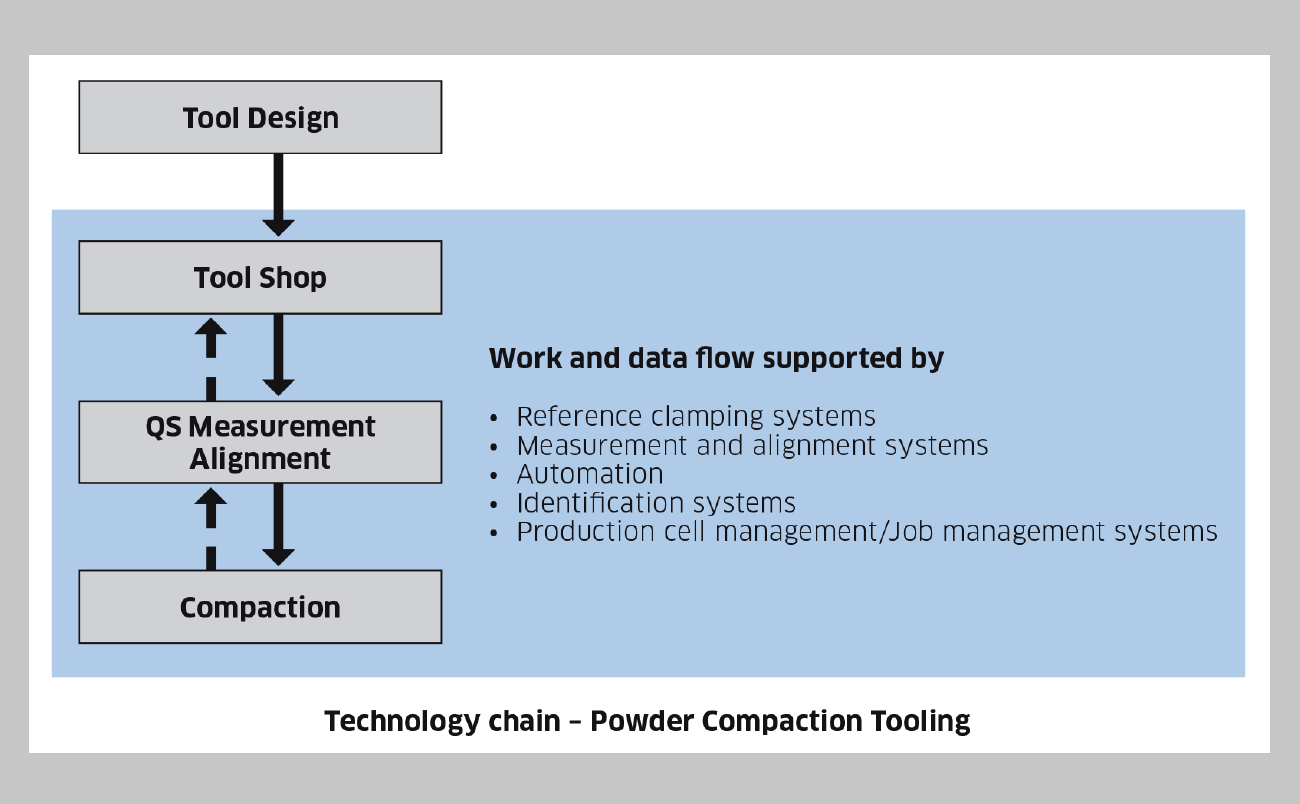

RFID / Work and Data Flow / Technology Chain

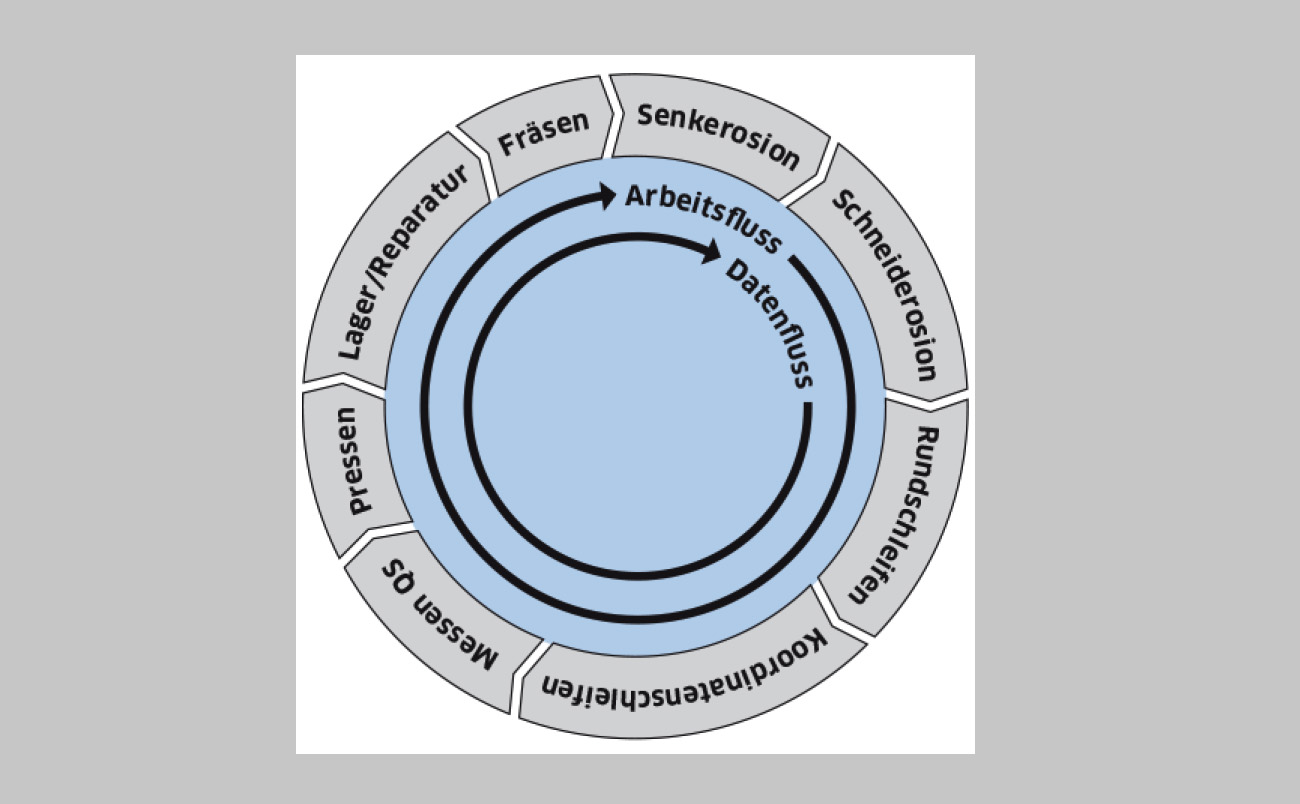

The continuous production of compaction tools on pallets places high demands on an optimal work and data flow from the tool shop up to the usage of the compaction tools in the press. Shortest set up times of machine tools combined with highest manufacturing precision reduces the tool manufacturing costs.

Adaptation and Equipment of Tool Shop for Full or Partial Integration

The Powder Compaction Tooling System works in the press with palletized and referenced compaction tools.

In the continuity of the manufacture and usage of compaction tools it can be distinguished between:

- Full integration

All machines of the tool shop are equipped on the machine table side with the Powder Compaction Tooling.

- Partial integration

The tool shop still manufactures compaction tools conventionally and is therefore not equipped with the Powder Compaction Tooling System. The compaction tools are connected with the pallets and positioned on the pallets in the quality assurance department by using the coordinate measuring machine and the palletization alignment system PAS 3i.

Full Integration and Partial Integration of Work and Data Flow

The Powder Compaction Tooling system can be operated as a full and a partial integrated system between the departments tool shop, press and quality assurance.

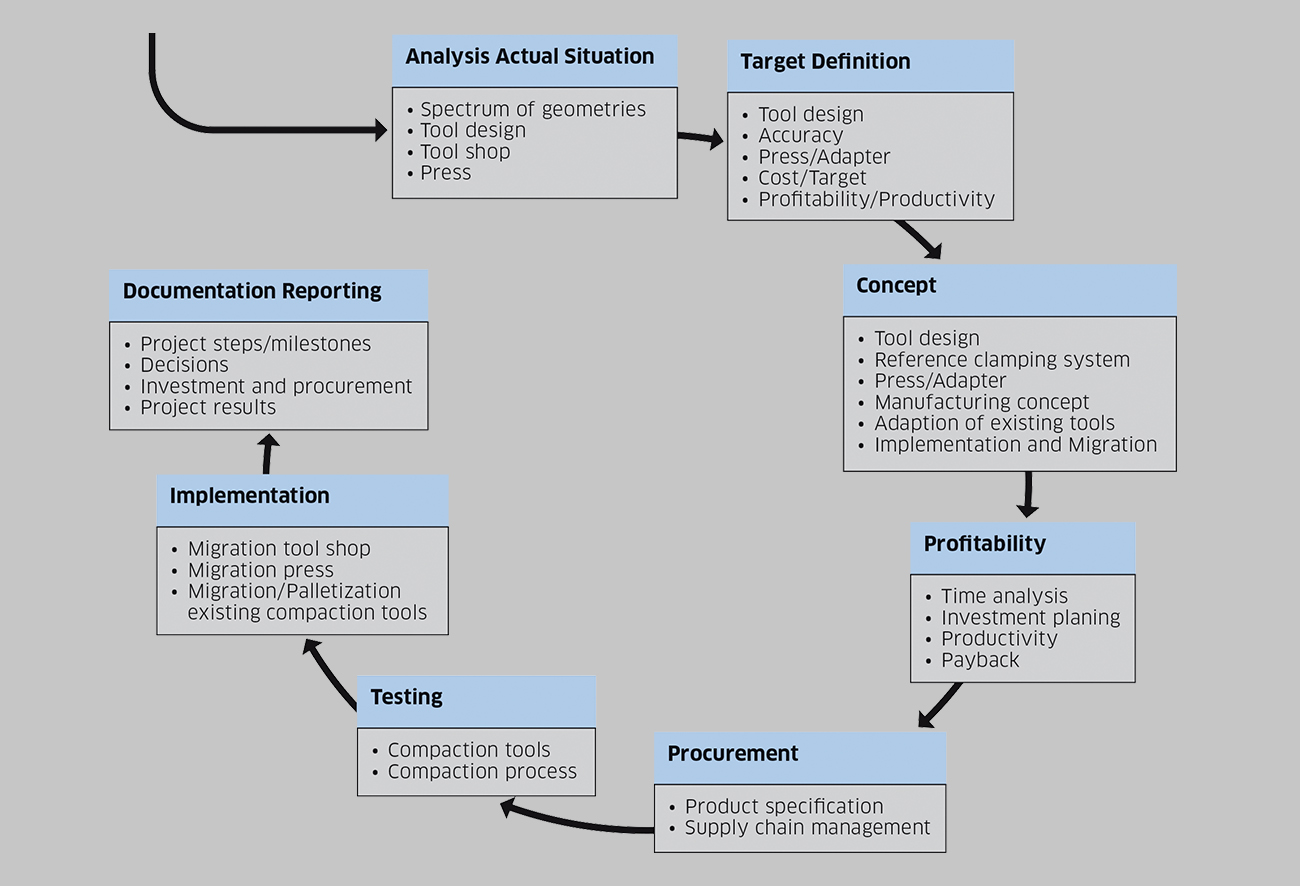

Integral 8 Step Powder Compaction Tooling System Approach

- Implementation of system analysis and evaluations in the area of compaction of metal and ceramic powder with reference clamping systems

- Implementation of cost-effectiveness, quality and precision improvement programs

- Support for problem analysis and troubleshooting

The integral 8 step Powder Compaction Tooling system approach by ProGrit is the turnkey for a complete system solution which fulfils the high demands on quality and productivity.

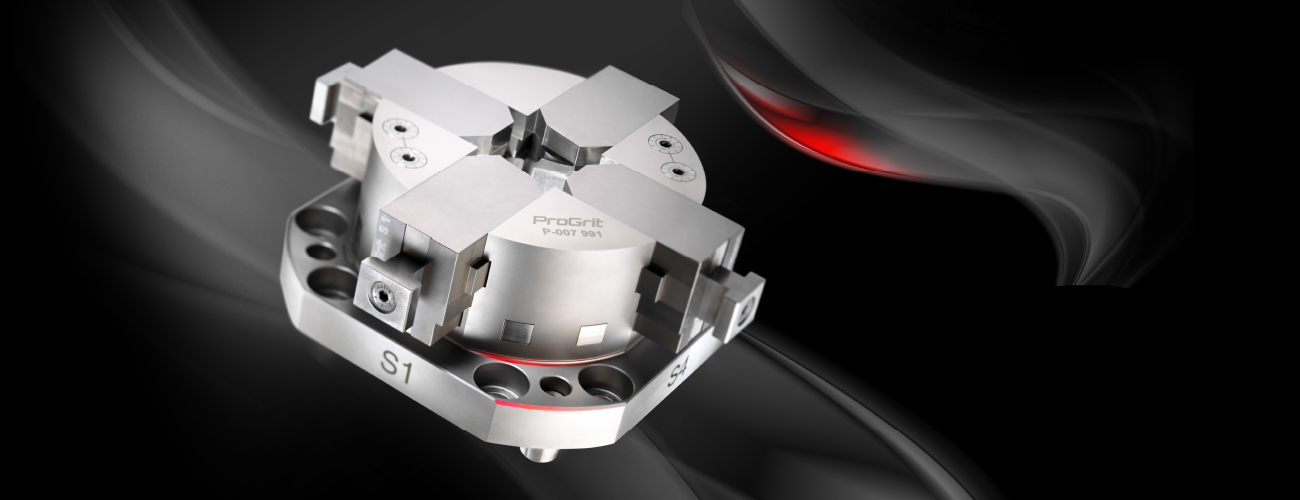

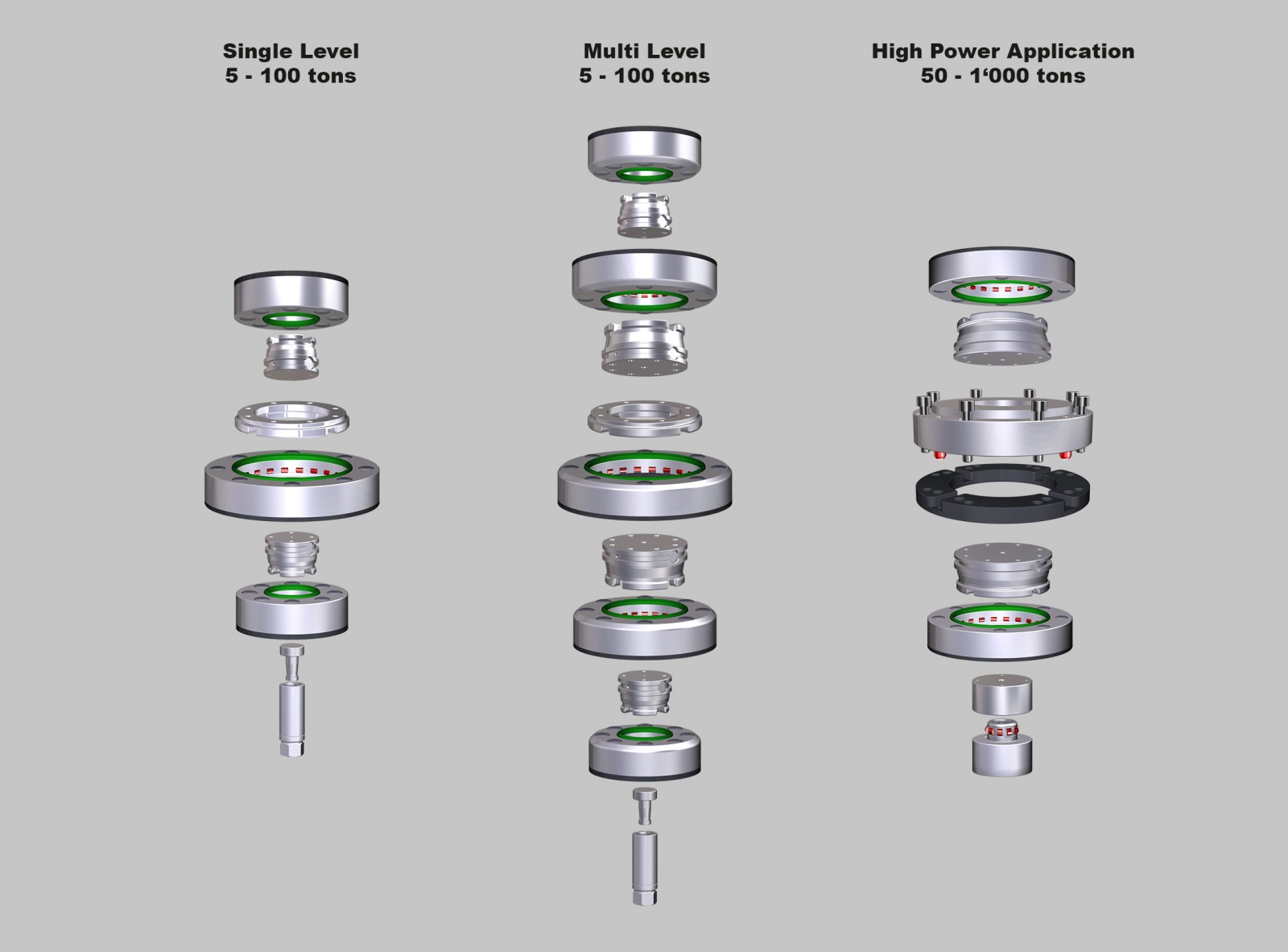

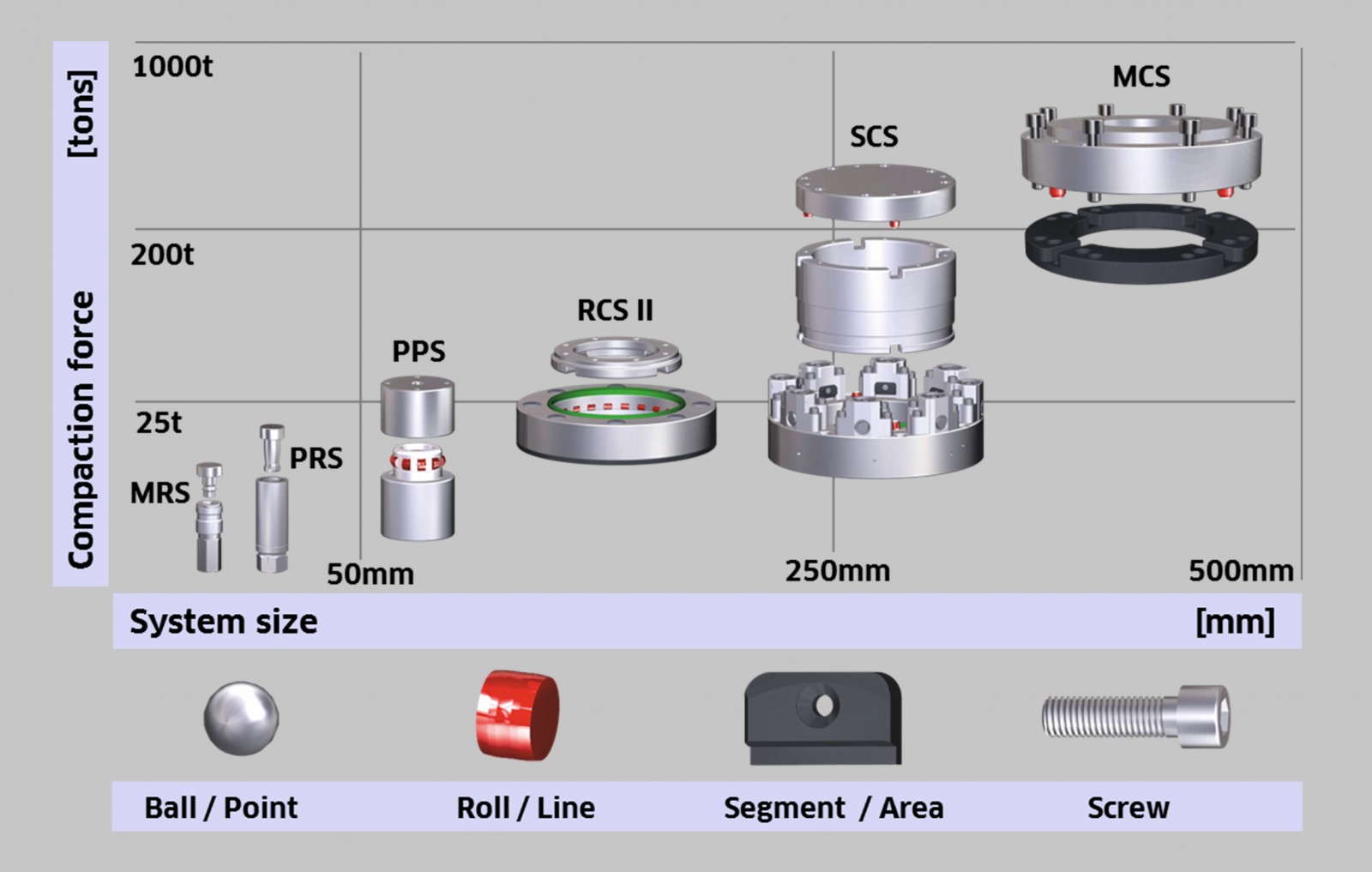

Reference Clamping Systems for Compaction Processes up to 1000 tons

Depending on the compaction forces the operating principle of the reference chuck will be adapted. The clamping element for the transmission of the clamping and extraction forces changes with increasing compaction forces from ball, roll to segments and screws.

Technical modifications reserved.

For a number of products of ProGrit GmbH, patents have been granted or are pending.

Copyright © ProGrit 2022

- Kastellstrasse 6 · 8623 Wetzikon / Switzerland ·

- Tel: +41 (0)44 844 54 26 ·

- info@progrit.ch

.jpg)

.jpg)