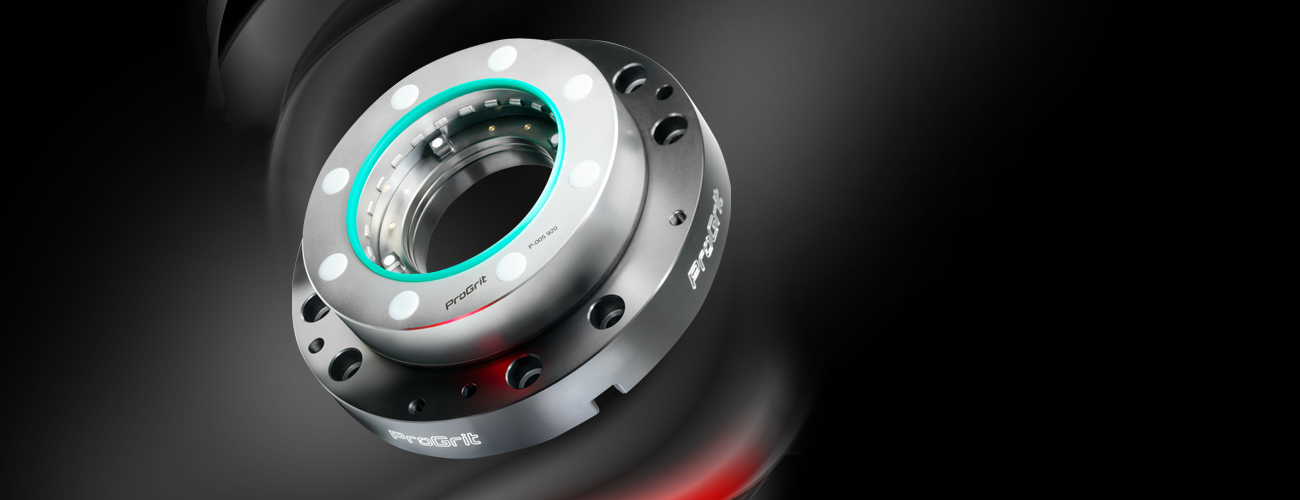

Optimization of grinding and conditioning processes

We advise you regarding your production issues in terms of conditioning and grinding techniques. Only an optimally conditioned grinding wheel will bring together with a suitable grinding process and machining parameters the desired result.

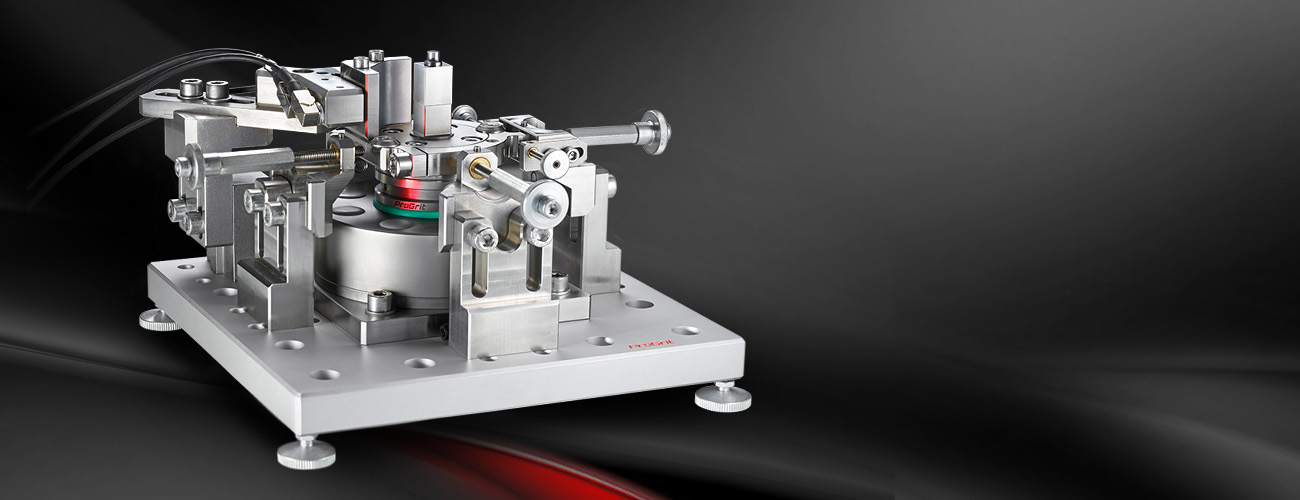

Improvement of the efficiency of grinding processes by reducing cycle times

The efficiency of grinding processes is influenced only by a small part by the cost of the grinding wheel. A much higher proportion is affected by incorrectly chosen machining parameters. This leads to unnecessarily high cycle times and damage the cutting edge of the incorrectly used abrasive grit. ProGrit helps you to reduce your cycle times.

Improvement of the quality of grinding processes - surface and edge quality

The improvement of surface and edge quality can be affected in a wide range by innovative conditioning techniques and grinding wheel concepts as well by intelligent selected machining parameters. ProGrit will help you to step in new dimensions of grinding quality.

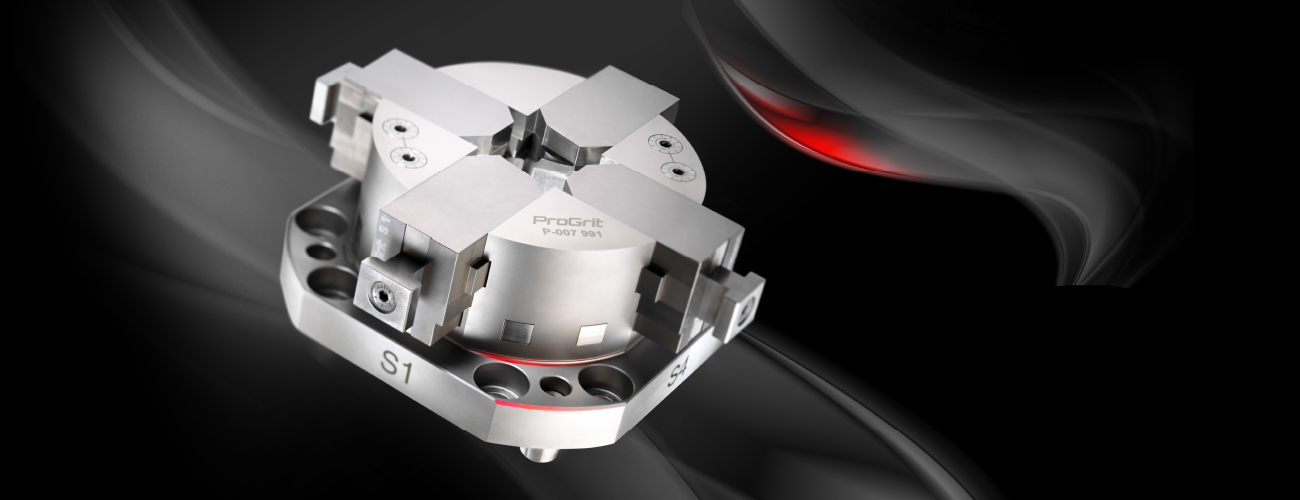

High Performance Grinding Technology / ECD Grinding / High Speed Grinding

There is a variety of high performance grinding methods to solve very difficult grinding tasks. ProGrit evaluates and adapts them to your production processes and machine conditions. The ECD grinding technology, developed by Dr. Dietmar Kramer, is one of the possibilities to solve difficult grinding tasks.

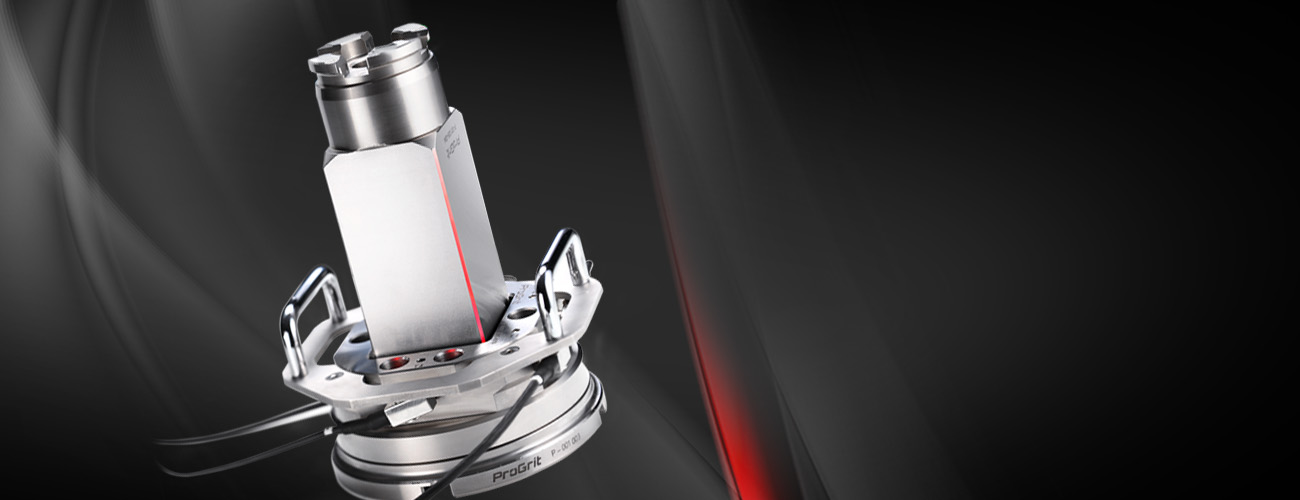

The ECD process uses a metal-bonded diamond or CBN grinding wheel and a dressing electrode. Between the grinding wheel and the electrode flows an electrically conductive coolant. The application of a voltage between the two electrodes leads to the dissolution of the metallic bonding system. The bonding of the grinding wheel is removed behind the grit peaks, dulled abrasive particles are released from the bonding, which produces an optimal protrusion of the grits. The ECD process can dress grinding wheels with very fine grit size (e.g. MD 4 - MD 10) and high concentration up to C(B) 200. The result is a cool grinding process combined with a high removal rates and best quality.

Ask for other possible solutions from ProGrit.

.jpg)

.jpg)